Most Amazon sellers, in the frenzy of adjusting PPC bids and retail price, overlook one hugely business-critical aspect: inventory management. More over, Amazon reserved inventory may not be considered at all.

Most Amazon sellers, in the frenzy of adjusting PPC bids and retail price, overlook one hugely business-critical aspect: inventory management. More over, Amazon reserved inventory may not be considered at all.

Going out of stock on Amazon severely hurts your ranking. Even slow assimilation of your goods into FBA warehouses can do some damage; it takes time for Amazon to receive your goods and distribute them to other Amazon fulfillment centers and prepare it for sale and shipping. During that time, your products are shown as being “In Stock” but available on a later date. Shoppers can’t get your product the next day or two which could hurt your conversion rates, known in Amazon-lingo as “Unit Session Percentage”.

Think about shoppers eagerly visiting your listing only to find that they can’t get it with next-day Prime shipping, but that’s it’s “Available on __ [some future date they don’t want to wait for]”. Inevitably, they’d click away.

Keeping a firm eye on your inventory levels is crucial. Now, let’s talk about what exactly these different stages of Amazon’s FBA inventory assimilation are, and how they affect your bottom line.

What is Amazon Reserved Inventory?

There are three different kinds of reserved statuses for your Amazon Reserved inventory.

The first is “Reserved – FC Processing” (“FC” stands for “Fulfillment Center”). This means that your FBA inventory has been received by Amazon and is being assimilated. When you ship your goods to Amazon’s warehouses (also called FBA warehouses or Fulfillment Centers), it’s not available for purchase that very same day. When it’s being unpacked, scanned in and sorted it’s in “Reserved – FC Processing” status, hence the term Amazon Reserved Inventory.

In some cases, Amazon sends portions of your inventory to its other Fulfillment Centers. Many sellers think that their inbound Fulfillment Center (the one address they ship their inbound goods to) determines their company’s tax nexus. But it’s a fact that Amazon then redistributes and stores your goods in other multiple centers. If you’d like to see a comprehensive guide on finding these Amazon Inventory Event Detail Reports, visit TaxJar’s article here.

This redistribution of your goods is “Reserved – FC Transfer”, which could cost you valuable availability time. There’s no hard and fast rule about how long Amazon takes to move your goods to other warehouses. It could take between 3 to 11 days, depending on the season and extraneous factors like inclement weather.

While your goods are being moved and appropriated into new warehouses, your goods will be listed for sale on Amazon. However, Prime members won’t be able to buy them using same or next day shipping. Instead, it shows the product will be “Available On….” message, which is displayed under the title on the product listing detail page.

The third kind of reserved inventory status is “Reserved – Customer Order” and obviously denotes the number of units that have been reserved for customers who’ve placed orders. These reserved units equal the number in your pending orders, found in your Order List.

Remember, though, that the quantity of Reserved for Customer Order don’t always end up being fulfilled since some customers’ payment methods might not process. That being said, don’t count your chickens before they hatch.

Where Do I Find My Amazon Reserved Inventory Levels?

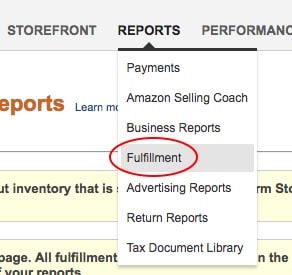

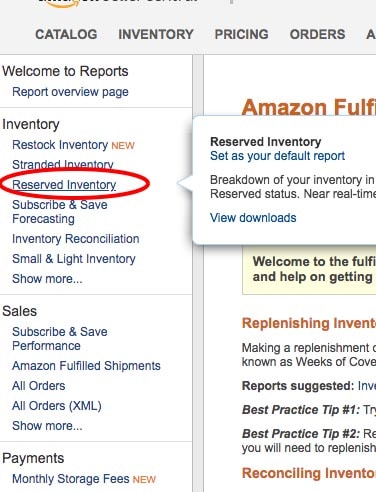

Log into your Amazon Seller Central account, then visit Reports > Fulfillment > Reserved Inventory.

Time Management Factors to Consider when Restocking Amazon Inventory

It’s not as easy as simply re-ordering when Amazon alerts you that your FBA inventory is low. By that time, it’s far too late to re-order.

1. Shipping method

If your supplier is in China, then you can ship via sea, air freight or air express. If you’re selling on Amazon’s EU marketplaces, then you can also ship your goods via train.

Shipping via sea from mainland China to the U.S. takes about 13 to 17 days on the water. Air express can take 3 to 5 days, and air freight 5 to 7 days.

2. Extra time allowance

But remember the extra time involved: getting your products from your supplier to a port in China, then when it docks in the U.S.A. it must pass customs inspection and be palletted and then transported further to Amazon’s warehouse. And even then, your shipping courier might be turned away on the day of scheduled delivery for whatever reason Amazon chooses.

3. Busy times of year create slower shipping

Don’t forget the Chinese New Year, when the entire country practically shuts down for all of February. Also, heavy shopping seasons such as Black Friday can lead to slower shipping times in the U.S.

4. Extraneous factors

Keep in mind that your supplier’s lead time may change, your shipping courier might not be 100% reliable, and independant third party inspection of your goods may take longer than planned.

Keeping all these factors in mind, a U.S. seller might have a spread of 80 to 110 days from the date when the order is placed with the supplier until it’s assimilated and ready for sale on Amazon.

Free Tools to Help You Keep an Eye on Your Amazon Inventory

A handy app to track the movement of your goods is AfterShip. It’s available on mobile and desktop, and free for up to 50 shipments / tracking numbers.

HelloProfit also has a helpful sales velocity notification feature which is included free in the monthly subscription. You can easily be notified by text message, email and in-app if your sales breach a certain level that you can set yourself.

What’s Your Experience Been So Far?

If you’re reading this post, then it’s safe to assume you’re an Amazon seller. What’s the longest FC processing time you’ve dealt with so far? And which shipping tracking service do you use, possibly even on a larger scale? We’d love to hear, just leave a comment below!

While we’re on the topic of inventory, here are some inventory management tools to help you restock your inventory effortlessly.